We Audited 100 POs

At HTG, we don't just print shirts. We obsess over what works, what breaks, and how to run smarter every single day.

Earlier this year, we ran an internal audit of 100 recent contract jobs across screen printing, embroidery, and DTF. We wanted to know:

Where do jobs go sideways? What slows things down? And what’s quietly killing profit margins without anyone noticing?

The results were eye-opening. Some of it we expected. Some of it caught us off guard. All of it can help you run a cleaner, faster, more profitable business.

1. 47% of Orders Had PO or Art Issues That Delayed Production

Nearly half the orders we reviewed had incomplete or unclear purchase orders and artwork files.

Missing PMS codes

Vague notes like "center chest" with no dimensions

Raster files instead of vector

Job names that didn’t match the art files

These aren’t small errors. They stall production, trigger email threads, and knock your order out of the press queue.

What no one talks about: These problems don’t just affect your job, they create bottlenecks for everyone behind you.

2. 22% of Client-Supplied Garments Arrived Incorrect or Late

Client-supplied garments are common—but they’re also one of the top sources of chaos.

Wrong styles or colors

Incomplete quantities

Late arrivals

No packing slips or communication

What no one talks about: Every time we have to sort, track, or delay a job due to garment issues, it adds labor cost. That eats your margin, even if you don’t see it directly.

3. 35% of Rush Orders Could Have Been Avoided

We get it—sometimes the client needs it yesterday.

But in over a third of rush jobs, the PO was submitted late even though the art and inventory were ready to go. The rush was self-inflicted.

What no one talks about: Rush fees are real, but so is the strain on production. If you’re not charging your customer for that urgency, it’s coming out of your profit.

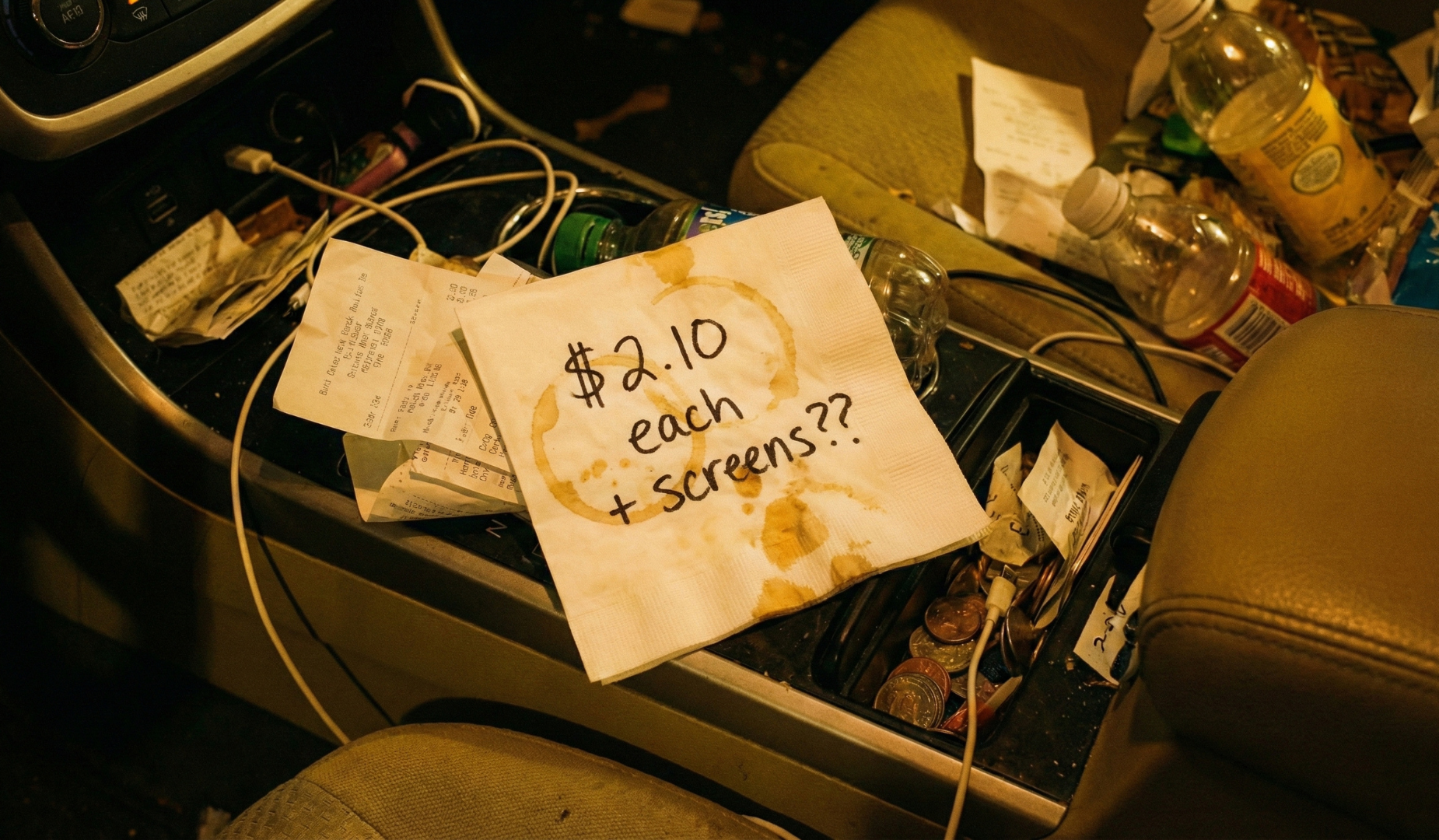

4. 61% of POs Included Add-Ons Without Pricing Clarity

We saw all kinds of value-adds on these orders:

Polybagging

Sleeve prints

Neck relabels

Patches

Special effect inks or threads

But in over half the POs, these were listed with no clear breakdown of how they were priced—or even if they were priced.

What no one talks about: If your PO is vague, you're likely absorbing the cost. That’s death by a thousand cuts.

5. The Clients with the Fewest Mistakes Sent the Clearest POs

The cleanest jobs had one thing in common—crystal-clear paperwork. Those clients:

Used structured PO templates

Attached mockups with detailed specs

Sent vector artwork with PMS codes

Listed every finishing detail upfront

They weren’t always our biggest clients, just the most organized.

What no one talks about: You don’t need to print more shirts. You need to print smarter ones.

Final Takeaway: Your Margin Lives or Dies in the Details

These weren’t flukes. They’re patterns. And they’re costing time, money, and client trust every day.

Want:

Faster turnarounds?

Fewer mistakes?

Better margins?

It all starts before your job hits the press.

We’re not here to point fingers, we’re here to help you win.